Industrial Burner

High efficiency industrial burner for various applications.

Biomass Stove

Biomass stove is generally used for vertical fire purpose . It is also known as vertical fire burner

2lkcal burner

Robust oil pump suitable for continuous operation.

Pressure Regulator

Precision pressure regulator for industrial use.

Flame Sensor

High-sensitivity flame sensor for safety systems.

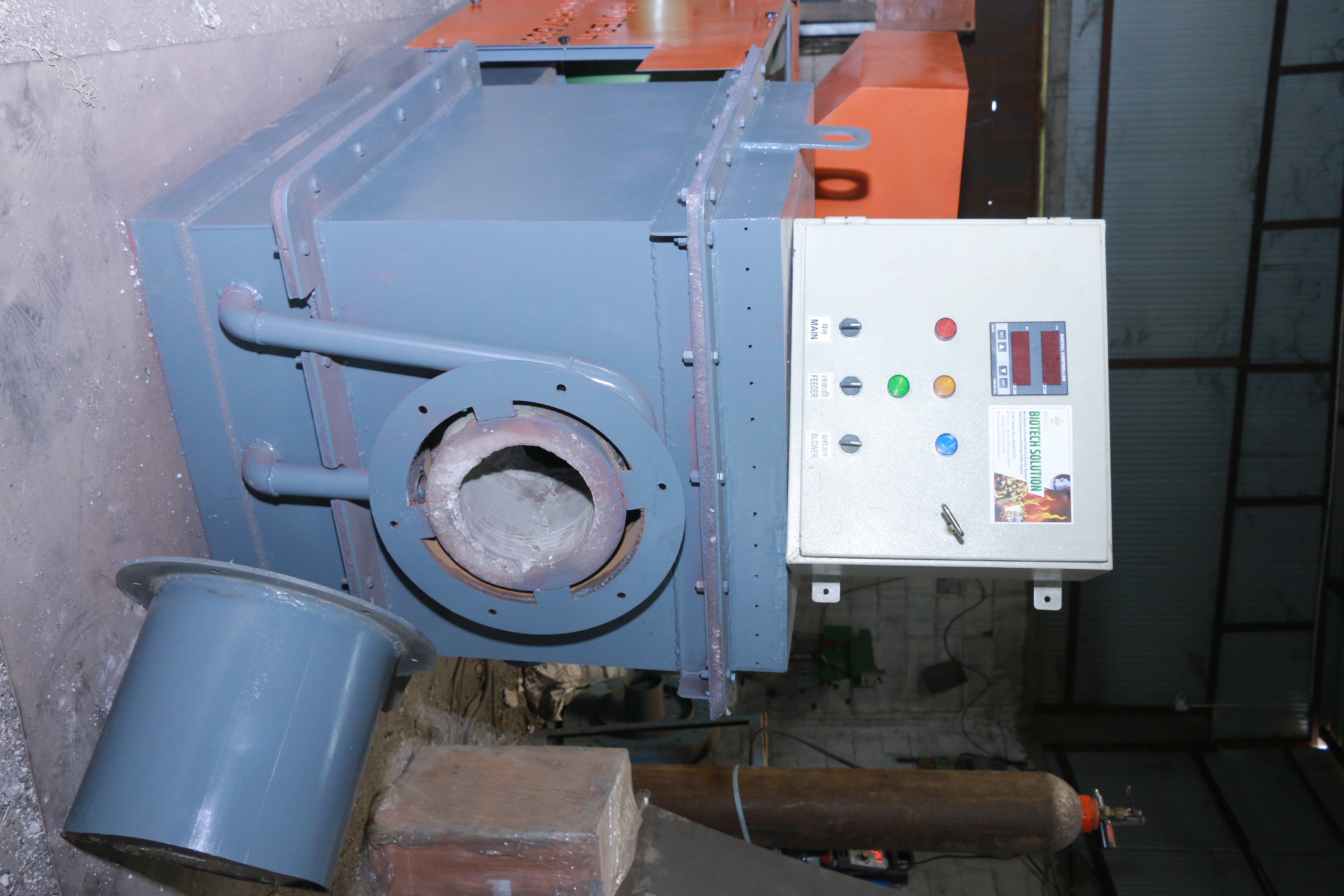

Control Panel

User-friendly control panel for burner management.

Air Blower

Efficient air blower for combustion support.

Nozzle

Precision-engineered nozzle for optimal fuel delivery.

Solenoid Valve

Fast-acting solenoid valve for fluid control.

1 lkcl biomass burner

Features -60% to 70% saving in fuel cost against LPG,DISEAL,LDO,FO,PNG Etc.... -Clean And Silent Operation -Zero Maintenance And Robust Design _Plc Control Panel With Safety Features _Auto Ignition And Auto Ash Removal System -Fully Automatic And Lower Power bConsumption

2 LKCL Industrial Burner

- Capacity -2,00,000/-Kcal/hr - With Plc Control Panel - Ovearall Dimension -Lenght 1800mm -Width 600mm -Height 1000mm - Power Rating in 0.75 KW, 3 Phase,440 Volt - Fuel Consumption Minimum 16 Kg/hr - Fuel Consumption Maximum 50 Kg/hr - Weigt Approximate 800 Kg - Fuel Type -Multifuel - Automatic Fuel Feeding - Automatic Temperature Control

3 LKCL Industrial Burner

- Capacity -3,00,000/-Kcal/hr - With Plc Control Panel - Ovearall Dimension -Lenght 1900mm -Width 700mm -Height 1100mm - Power Rating in 1.5 Hp, 3 Phase,440 Volt - Fuel Consumption Minimum 25 Kg/hr - Fuel Consumption Maximum 75 Kg/hr - Weigt Approximate 900 Kg - Fuel Type -Multifuel - Automatic Fuel Feeding - Automatic Temperature Control

4LKCL Industrial Burner

- Capacity -4,00,000/-Kcal/hr - With Plc Control Panel - Ovearall Dimension -Lenght 2000mm -Width 800mm -Height 1300mm - Power Rating in 2HP , 3 Phase,440 Volt - Fuel Consumption Minimum 33 Kg/hr - Fuel Consumption Maximum 100 Kg/hr - Weigt Approximate 1000 Kg - Fuel Type -Multifuel - Automatic Fuel Feeding - Automatic Temperature Control

5 LKCL Industrial Burner

- Capacity -5,00,000/-Kcal/hr - With Plc Control Panel - Ovearall Dimension -Lenght 2000mm -Width 900mm -Height 1400mm - Power Rating in 2.5Hp, 3 Phase,440 Volt - Fuel Consumption Minimum 40 Kg/hr - Fuel Consumption Maximum 125 Kg/hr - Weigt Approximate 1200 Kg - Fuel Type -Multifuel - Automatic Fuel Feeding - Automatic Temperature Control

6 LKCL Industrial Burner

- Capacity -6,00,000/-Kcal/hr - With Plc Control Panel - Ovearall Dimension -Lenght 2200mm -Width 1100mm -Height 1500mm - Power Rating in 3.5Hp, 3 Phase,440 Volt - Fuel Consumption Minimum 50 Kg/hr - Fuel Consumption Maximum 150 Kg/hr - Weigt Approximate 1400 Kg - Fuel Type -Multifuel - Automatic Fuel Feeding - Automatic Temperature Control

Hotel Line Stove

A pellet stove is a heating appliance that burns compressed biomass or wood pellets fed automatically from a storage hopper into a chember, producing constant, efficient heat with minimal smoke and ash. They are easy to operate, offer high energy efficiency (over 90% is common), are considered environmentally friendly. Working- -Fuel Storage: Pellets are stored in a hopper. -Combustion: A blower fan pushes air into the burn pot for a hot, clean burn, creating heat. -A small exhaust pipe vents gases outside. -High Efficiency: Modern pellet stoves can reach over 90% efficiency. -Clean Burning

Hot Air Generator

-Fully Automatic System -User Friendly System -Upto 60% fuel saving Against Diseal & Gas -Specilly Design According to Biomass Pellet -Use For All Printing/Coating & Drying Process Uses -Rotogravour, Tape Coating,Paper Coating -Textile Industries -Fryums Drying & Papad Drying Technical Details- -Max.Hot Air Outlet Temp Upto 400 degrees -Thermal Efficiency On GCV -Electric Supply 440Volt, 3Phase,4 Wire -Fuel Firing On Gas And Pellet -Hot Air Type Direct & Indirect